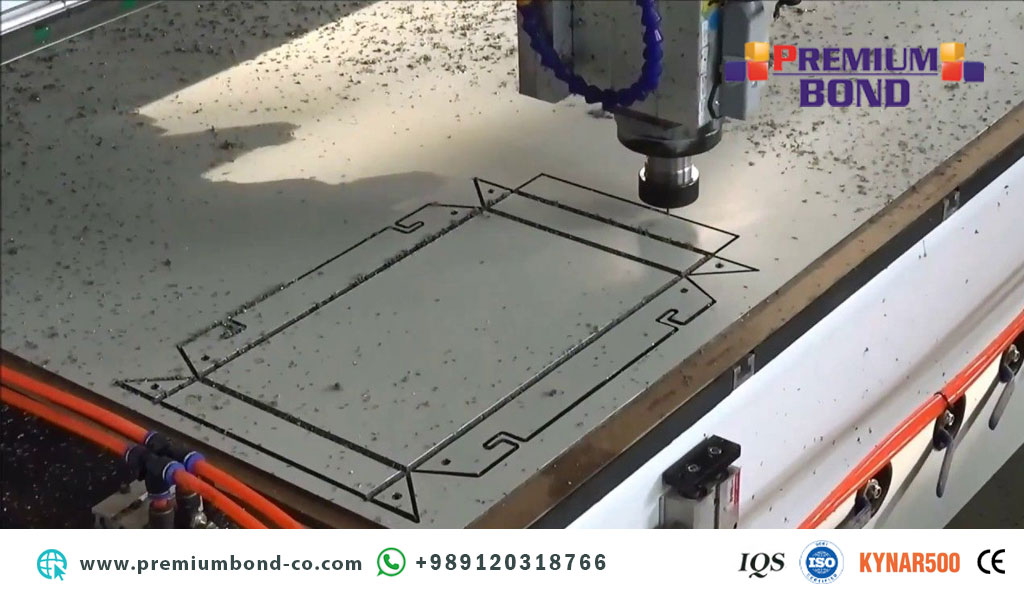

CNC composite cutting

cutting tools for composite materials

CNC composite cutting

When it comes to using composite to implement building facades,

How to supply this material is also considered

And companies that are active in building facades with aluminum composite sheets.

They definitely need to explain to the customer how these materials are supplied

And how they are distributed to the consumer market in different dimensions and designs.

Many companies involved in this field are equipped with devices and tools that are used to cut composite sheets.

CNC cutting machine

With the help of these devices, metal sheets can be cut and used in different sizes and thicknesses according to the needs of each project.

Using laser cutting techniques or CNC punching presses, the process of cutting sheets will be done in a very accurate and acceptable quality.

And of course, in order to get the desired result, it is necessary for specialized and trained people to work with these tools.

Usually, most CNC cutting machines have the ability to cut all kinds of aluminum, iron, steel, brass, etc. composite sheets.

And they can do that on a pre-determined and pre-determined scale.

Because these tools are directly controlled by computers and related applications,

It will also have a very high accuracy.

If laser beams are used to cut composite sheets,

Eventually, the result will be perfectly acceptable

And this method has the ability to cut several sheets simultaneously by it

Without reducing the quality of work.

The use of such new tools reduces the need for manpower in addition to speeding things up

And the CNC cutting machine can perform various steps completely automatically

And in addition to increasing productivity and productivity, increasing the speed of work and increasing customer satisfaction, time can be managed optimally.

Aluminum sheet punch

If you search the Internet, you’ll see examples of composite building facades using CNC punches.

In larger samples that have been implemented for industrial, commercial, recreational, etc. projects

It has a special beauty and in addition, it has tried to combine creativity and innovation with today’s technology.

Punch CNC is a modern device

Used for cutting aluminum composite sheets

And it can be used to cut two-dimensional shapes that have already been designed using specialized software on these sheets.

Through the punch, pieces are separated from the sheet metal to create the desired design.

There are no restrictions on the implementation of various projects.

Since CNC punches need to be paid after punching parts,

The system and how this device works is as follows

The cut sections will be very flat and smooth

And that’s why this method has a high quality and low error rate

Of course, in this case, the role of computer programs related to the aluminum sheet punching machine cannot be ignored.

With the advent of computer technology, we are witnessing a decrease in human error and an increase in the speed of cutting all kinds of metal sheets

And with the CNC cutting and punching machine, in addition to replacing the appropriate method to reduce the use of manual and traditional tools,

It is possible to implement and implement what is appropriate to the needs and tastes of dear employers.

Of course, we can guarantee that this increase in speed is accompanied by maintaining the quality of the product.

How do you cut composite material?

A variety of different methods can be used to cut uncured composite materials. The most well established is the use of an automated ply cutting table. This consists of a ‘moving bed’ with a cutting gantry that runs above the bed. The gantry houses either an ultrasonic cutter or a ‘powered wheel’ cut.

Composite cutting machine

CNC cutting machines are generally associated with metal parts tooling…or eventually with stone parts tooling. However, two cutting technologies – waterjet cutting and laser cutting allow tooling of more kinds of materials. Interesting example are plastics. They are used in industry more and more often, mainly because of their features. Very desirable are materials which keep high strength level but still stay light and flexible. What are they in tooling process? Is it possible to cut them alike?

Leave a Reply