History of ACP

Aluminum Composite Panel in Iran

Composite facade has been entering the Iranian market for more than 15 years.

At first, some wealthy Iranians who were active in construction

In search of a new facade with more efficiency than the products of that time, they occasionally imported and executed composite facades for their personal projects.

After that, some trading companies started importing and selling this product.

Alcobond, Alclad, Alpulic, Mitsubishi and Albond, etc. are among these brands.

After a few years, with the increase in domestic demand and a significant increase in imports of this product (more than 50 different brands)

Some domestic manufacturers have started to produce composite aluminum sheets in Iran and to equip their factories and produce this product.

Domestic production plants

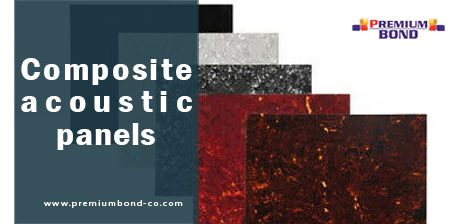

After that, more factories started to produce composite aluminum sheets

Including premium bond, alumax, alubond, etc., which number more than 20.

Of course, a significant number of factories were forced to close

and leave the field due to the competitive environment created

and the lack of flexibility, as well as the production of low-quality products.

Currently, about 15 fully active factories in the whole country produce composites,

and in a way, it can be said that these factories produce all domestic brands, which number more than 20 brands.

In this way, some companies that have a good history and experience in the Iranian market have started to register the brand and produce their composite sheets in the form of outsourcing production by other domestic production factories,

which is one of the positive points in It is the economy that has led to lower costs, higher employment and factory inactivity.

As you know, the cost of designing a building facade is the best investment in building construction,

because designing an attractive and beautiful facade can dramatically increase the value of any building.

Since the design and implementation of the facade of modern European buildings is very expensive

and many of them are not compatible with the climatic conditions and widely used materials in Iran,

it is better to follow the photos and facade designs of Iranian buildings to model the facade of the building.

In designing Iranian facades, there is a difference in cost and geographical location,

but it is quite clear that it is easy to follow the ideas and designs of Iranian facades to get closer to success.

Comments (3)

Aluminum thickness 0.21mm

Panel thickness 4 mm

Width 1220mm

Length 2440mm

Square meters 30000 m2 at the week

50 piss 4×12

Mrp btao

Hello sir i need premium Acp 4mm and coil 0.3mm

+923212140129