What is aluminum composite sheet?

What is an aluminum composite?

What is aluminum composite sheet? It can be said that:

Aluminum composite sheet is a building facade material.

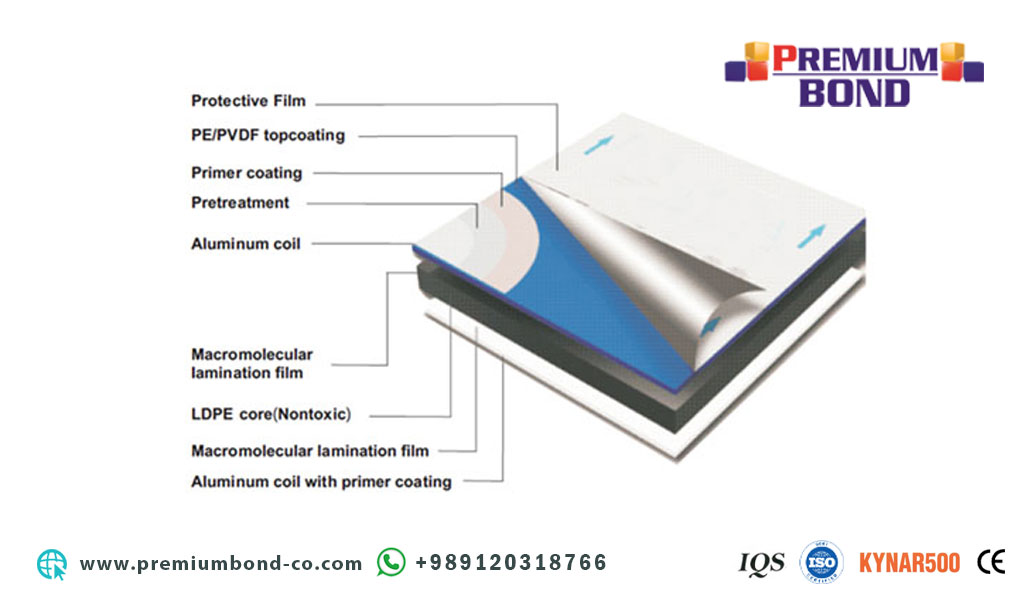

It consists of a foam-like core surrounded by two outer aluminum shells.

These panels share many features in common with wooden sandwich panels.

But they have a higher resistance to weight ratio.

The core of these panels consists of an insulating foam such as polyethylene or polystyrene.

Both are effective in reducing heat transfer through the wall.

By combining this insulating core and aluminum shells into a single panel, building builders and facade installers are able to display the walls and other parts of the building at high speed and ease of execution.

Features of composite sheet aluminum panel

– Extremely twisted strength of premium bond aluminum composite sheet:

Using a variety of advanced production and control equipment, this product has been able to show good resistance to bending, bending and traction under heavy loads.

– Easy preparation and installation of premium bond aluminum composite sheet:

The weight of each square meter of composite sheet depends on the thickness between 5.2 and 5.5 kg.

That’s why it’s so easy to make a composite sheet

All drilling, groweing, cutting and bending can be done with simple tools.

For this reason, the exterior and interior decoration can be done simultaneously, and the efficiency of the work is increased and less time is spent.

– Fire resistance of aluminum foil composite premium bond:

Fireproof composite sheet due to the presence of polyvinyl plastic layer among itself (without the use of toxic substances) and also with the coating of non-flammable aluminum layer on both sides has fire resistance and is actually fireproof and safe product and the need for resistance Fulfills the building rules and regulations against fire.

– Excellent resistance to impact of aluminum foil composite premium bond:

Composite sheets have a good impact resistance and are resistant to crushing and crushing, as well as not being damaged by severe sand and wind storms.

– Resistance to atmospheric currents of aluminum foil composite premium bond:

Due to the protective coating (P.V.D.F), the composite sheet shows good alkaline resistance against UV rays and acid rain, so this product can be used for a very long time without changing the color.

– Uniform coating, stability and variety in color of aluminum foil composite premium bond:

Using a uniform aluminum surface and using the latest technology in the world, this product has provided access to a variety of metallic colors, seven colors, wood and stone designs. To paint the panels, a very advanced and high quality system has been used so that the desired color has the highest quality and the most resistance to adverse weather conditions, industrial pollution and ultraviolet radiation, so that in the long run the beauty of the building facade for years. In the same way, it will remain the same and will not be different from the first days.

– Simple maintenance of premium bond aluminum composite sheet:

The composite sheet is resistant to contamination. The surface of these sheets should be cleaned after several years of use. All you need to clean these surfaces is water and neutral cleaners. After the cleaning operation, the surface of the sheet becomes like the first day.

What is a composite sheet?

An aluminum composite panel is a building material that features a foam core surrounded by an outer aluminum skin. These panels share many characteristics with wooden sandwich panels, but generally offer a higher strength-to-weight ratio. The core of these panels consists of an insulating foam, such as polyethylene or polystyrene, both of which are effective at reducing thermal transfer through walls. By combining insulation and aluminum panels into a single material, manufacturers allow installers to quickly and easily construct walls and other building features.

Leave a Reply