Types of sealing composite aluminum facades

We have different types of sealing composite aluminum facades

sealing the facade of the building is one of the principles of project engineering

The infiltration of hot and cold air as well as water into the building will reduce the comfort of the occupants and increase fuel consumption by up to 25 percent.

Sealing and sealing the facade of the building according to the climate is as follows:

- Replacing the glass and sealing and sealing the facade of the glass building with special adhesives resistant to uv at height without the need for scaffolding

- Replacing the opening openings of the facade of the frameless building and the facade of the Curtin Wall building at a height

- Complete waterproofing of structures using nanotechnology

- Cover the seam of the building

- Reconstruction and restoration of building facades

- Staining and cementing at height

- Building Facade Insulation (Moisture Insulation, Heat Insulation, Sound Insulation)

- Strengthening and waterproofing the exterior surfaces of the building against atmospheric factors (closing the facade of the building, filling the space between the stones with mortar of the same color to prevent water penetration into the facade of the building)

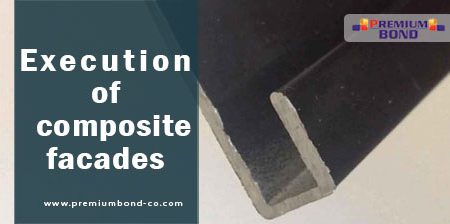

There are three types of seals :

Silicone foam and glue (mastic or aquarium glue) :

First, the foam foam is placed inside the strap and after the special pump,

the silicone glue is pumped into the groove of the pump and at the same time it is cleaned and

smoothed with special tools. The adhesives have several colors that are selected according to the color of the sheets.

Sealing rubber :

These tires, which are slightly larger in thickness than the groove, are made of PVC or silicone, and silicone adhesives are used to keep them in place for a long time.

Belts or studs :

The belts or studs themselves are cut and made of composite sheet with a range of available colors and placed inside the groove.

Comment (1)

[…] Sealing : […]