Problems separating composite sheet labels

Solve the problem of separating composite sheet labels

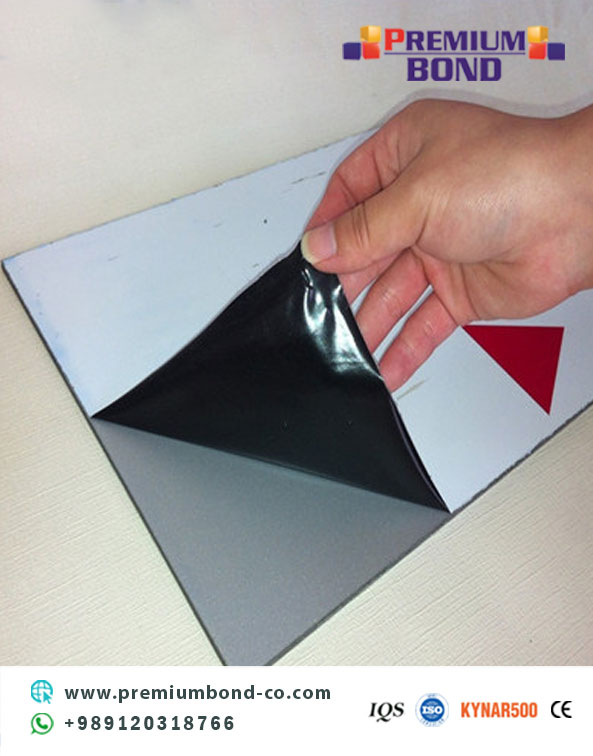

One of the problems that composite sheet may have after its execution is separating the label from the composite sheet.

One of the things that many colleagues in the facade, especially aluminum composite panel, face from time to time, is the Problems separating Aluminum composite sheet labels.

Lack of easy separation of the film’s protective layers from the primary layers of the Aluminum composite sheet

Or leaving traces of such labels on the facade, which sometimes causes

The newly built facade of a high-cost building has an unpleasant appearance

And sometimes the employer or executor has to implement the sheet and reinstall it.

You need to know that there are many such cases

There may be many things, such as not using the right type of sheet coating

For all types of solid, metallic and shin sheets by the manufacturer

Also, do not cover the sheet in time and expose it to sunlight, or even cause extreme temperature fluctuations and cold.

In the face of such cases, one must first examine the type of problem

And depending on the deterioration of the conditions, he applied the following steps for cleaning:

1- Pumping and spraying relatively hot water with intense pressure when we cannot lift the edges of the cover.

2- Using industrial hair dryers with caution and appropriate heat when the sheet coating is fragmented during separation.

3- Cleaning with super gasoline and rough cloth (only this type of gasoline is recommended due to not creating greasy stains) when the label stays.

4 – Using a strong thinner ٢٠٠٠٠ when pieces of veneer remain.

5 – Use ethyl methyl solution when the coating is not removed in any way.

6- Finally mixing the external xylene solution with the appropriate amount of water and using it when none of the above methods work.

Leave a Reply