Aluminum Composite Panels (ACP) Guide: Prices, Materials & Installation

Introduction – What Are Aluminum Composite Panels (ACP)?

Aluminum composite panels material

Explain the applications of ACP. Use bullet points for better readability.

Uses of Aluminum Composite Panels

🔹 Building Facades / Cladding

ACP is the most popular material for exterior building cladding because it is durable, weather‑resistant, UV‑resistant and lightweight.

🔹 Interior Decoration

Used for ceilings, wall panels, partitions, furniture fronts, reception desks, etc. ACP can be printed with high‑resolution images or patterns.

🔹 Signage & Advertising

Because of its smooth surface, ACP is ideal for outdoor and indoor billboards, shop signs, and event banners.

🔹 Transport

Applied on the exterior and interior of buses, trains, metro cars and aircraft for decoration and protection.

🔹 Industrial Equipment & Furniture

Covers for machines, office furniture, and outdoor benches.

Making composite aluminum panels, which today has a special place due to the variety of colors, lightness, weather resistance and good formability, has caused many domestic panel makers to use composite aluminum sheet as the main body of the panel.

Aluminum Composite Panel Structure and Materials

Structure of Aluminum Composite Panels

Every ACP consists of three layers:

1. Front Aluminium Layer

- Made from aluminium alloy (most commonly 3003 or 5005).

- Thickness: 0.5 mm – 1.0 mm.

- Finishes: Anodized, Powder Coated, Brushed, Embossed, etc.

2. Core (Middle Layer)

The core is the non‑aluminium part. There are 3 types of cores:

🔸 PE (Polyethylene)

- Cheapest option.

- Less fire resistant – NOT suitable for projects with fire safety regulations.

🔸 PU (Polyurethane)

- Better fire resistance than PE.

- Better colour fastness and gloss retention.

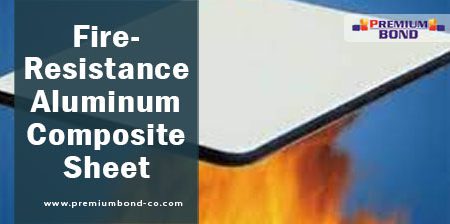

🔸 FR (Fire Retardant)

- Contains fire‑retardant chemicals.

- Mandatory for public buildings, hotels, hospitals and any project that follows strict fire safety standards.

Core Thickness: 2 mm – 6 mm depending on the application.

3. Back Aluminium Layer

Identical to the front layer.

Aluminum Composite Panels Price

Factors Affecting ACP Price

- Size – Standard sizes are 4ft x 8ft (1250 mm x 3200 mm), 8ft x 8ft, etc.

- Thickness – 0.5 mm vs 1.0 mm.

- Core Type – PE < PU < FR

- Surface Finish – Powder coated > Anodized > Brushed

- Quantity – Bulk orders have lower prices.

- Brand – Brands like Alucobond, Reynobond, Alpolic have premium pricing.

Aluminum Composite Panel 4×8 Price (2024)

Below you will find the average price for a 4ft x 8ft (1250 x 3200 mm) panel. Prices may vary depending on your country and supplier.

| Surface Finish | Core Type | Price per 4×8 Panel (USD) |

|---|---|---|

| Anodized | PE | $18 – $22 |

| Powder Coated | PU | $28 – $35 |

| Powder Coated | FR | $38 – $50 |

| Brushed | PE | $20 – $26 |

| Embossed | PU | $30 – $38 |

📊 Price per Square Metre

If you prefer price per m², here is an example for Powder Coated PU panels: $35 – $45 / m².

📌 Tip:

Add a price calculator on your page. Readers can enter the required size and get an estimated price.

Advantages of composite panel:

A) A light, durable and durable alloy

B) Ability to be formed and shaped with modern and up-to-date views of the world

C) Variety in color scheme of materials and suitable for any type of building facade

D) A suitable cover and bed for installing all kinds of advertising letters

R) Coverage for interior facades and roof surfaces

I) Suitable connections for any type of infrastructure

Aluminium Composite Panel Material

✅ Aluminium Alloy

The most common alloys are 3003 and 5005. They are non‑corrosive, strong and have excellent formability.

✅ Surface Finishes

Below are the most popular finishes. Explain each briefly:

🔸 Anodized – Increases thickness and protects against UV, abrasion and corrosion.

🔸 Powder Coated – Provides a wide range of colours and a matte or glossy finish. Most widely used.

🔸 Brushed – Gives a wood‑like texture.

🔸 Embossed – Creates a pattern (e.g., stone, wood, metal) on the surface.

It is a combination of two or more substances, one phase of which is composed of the main bonded particles and the other phase is the enclosing substance. Composite panels mainly include the following components:

1. Infrastructure materials: including hardware and fittings

2. Composite sheet or coating

3. Abundant materials and protective layer

Common Uses of Aluminum Composite Panels

Structure this as a practical list:

- Exterior cladding / curtain walls

- Signage and display boards

- Interior decoration and furniture elements

- Corporate identity panels, column covers, ceiling panels

Aluminum Composite Panel Installation Details

There are two main installation methods:

Method 1 – Adhesive Installation

Best for flat, smooth surfaces.

Tools Required:

- PU/Adhesive glue

- Paint roller

- Measuring tape

- Level

Steps

- Surface Preparation

Clean the surface thoroughly. It must be dust‑free and stable. - Apply Adhesive

Apply a thin, even layer of PU adhesive on the surface with a roller. - Place the Panel

Position the ACP panel on the adhesive. Press firmly for 30 seconds to ensure strong bonding. - Cutting (if required)

Use a circular saw or router to cut the panel to size.

✅ Advantages – Very fast, no visible screws.

Method 2 – Mechanical Fixation (Screw / Clip System)

Best when you need to allow for movement or future removal (e.g. signage).

Tools Required:

- Screws / Clips

- Drill

- Measuring tape

- Level

Steps

- Mark Fixation Points

Mark points on the surface 100‑150 mm apart. - Drill Holes

Drill holes at the marked points. - Fix Panels

Attach the panel using screws or special ACP clips.

📌 Important Installation Notes

🔹 Fire Safety – For buildings with fire‑safety regulations, always use FR core panels.

🔹 Spacing – Keep a small gap (2‑3 mm) between panels for water drainage.

🔹 Avoid Over Tightening Screws – It can damage the aluminium surface.

Advantages of Aluminum Composite Sheet :

1- Long life (20 years warranty)

2- Unique view in all colors compared to the job

3- Flexible in any shape and any size compared to the design

4- Strong against cold, heat and excessive rain

5- Washable

Important points in the implementation of composite boards:

– One of the most important items to choose is the material and quality of aluminum composite sheet, which should be one of the famous brands such as Premium Bond.

– Proper use of substructure materials for composite aluminum panel body

– Considering the pattern of composite sheet cutting and regular rows in the execution of the straps

– Proper sealing and slope of the board in all directions

– Avoid extra cuts

– Persian removal of panel failures for facade beauty

Aluminum composite panels near me

If you are looking to buy composite aluminum sheet but you do not know where to get it, we suggest a Google search for aluminum composite panels near me .

Frequently Asked Questions (FAQ)

Aluminum Composite Panels are mainly used for building facades, interior decoration, signage, transport, and industrial equipment

PE is cheaper but has lower fire resistance. PU has better fire resistance and colour retention.

Depending on the finish and core, the price ranges from $18 to $50 per panel

With adhesive, installation of a single panel takes 15‑30 minutes. Mechanical fixation takes a little longer.

Only panels with FR (Fire Retardant) core are fire safe. Always use FR core for public buildings.

Comment (1)

[…] Aluminum also oxidizes under normal conditions So that in the presence of air and usually a layer of oxide is formed in a non-porous manner on the surfaces of aluminum parts. […]