Technical Specification for Aluminium Composite Panel

aluminium composite panel technical specification

Resistance to temperature changes Due to its unique characteristics, it can withstand temperature changes from -50 to 80 + without any change in quality. Moisture insulation The space between the composite sheets and the wall of the building creates thermal and acoustic insulation and creates the possibility of air flow behind the composite panels, which prevents the ambient heat from penetrating the building.

Advantages of composite aluminum sheets – Possibility of quick and easy installation – Variety of colors – Possibility of various types of bending, perforation and cutting – Light and easy transportation – Less weight than other building materials – Easy to wash – Various dimensions – Thermal insulation and Audio – Earthquake Resistant – Fireproof Aluminum Sheets Composite Premium Band with PVDF Coating. PE and polyester.

The best available veneer is PVDF veneer;

Because PE coated sheets are opaque and opaque

And polyester coated sheets are also very resistant to light.

The thicker the coating, the longer the sheet will last.

Application

- Office, commercial, industrial, educational, health buildings, airports, terminals, metro stations, domes and special buildings

- Along with new technologies, architects’ interests and customer demands, construction materials are constantly being developed.

What is Technical Specification for Aluminium Composite Panel?

The premium bond composite sheet bonds at high temperatures with high-performance molecular hardeners to achieve the highest level of resistance to decay and discoloration.

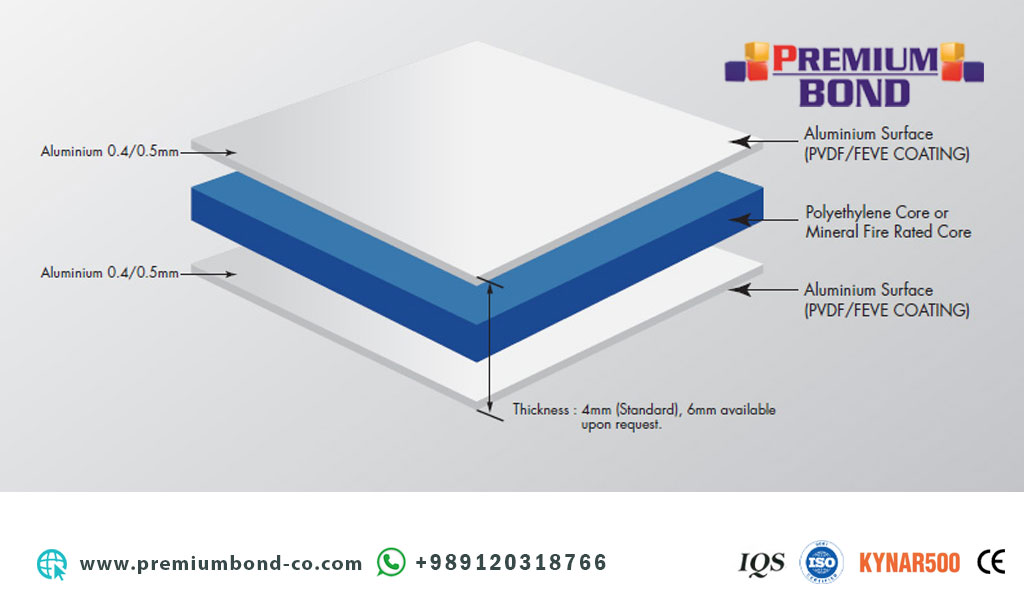

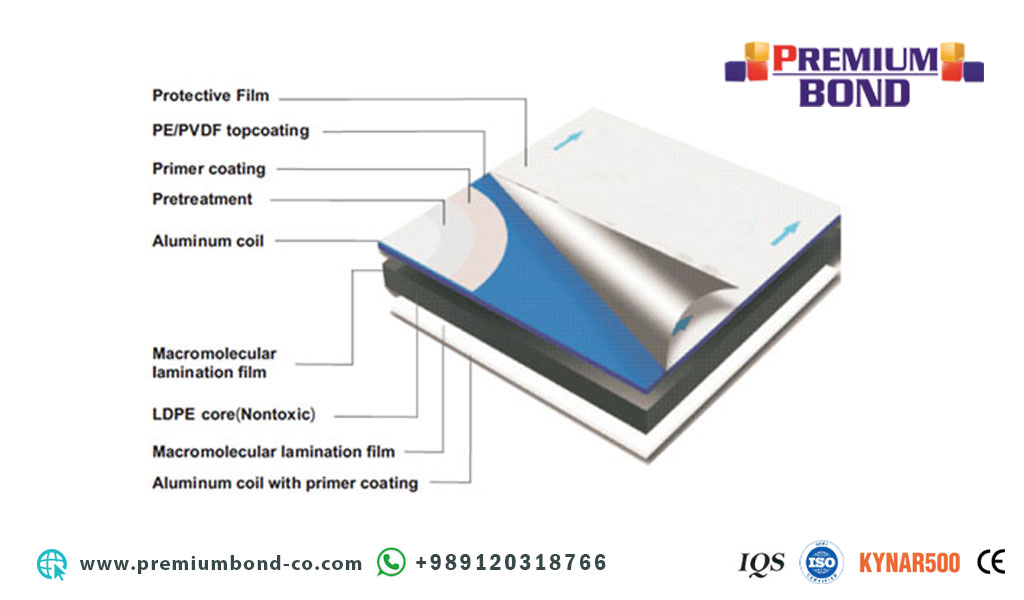

Premium Bond Composite Sheet consists of 9 layers,

which are multi-layer paint or coating, three layers of glue,

two layers of aluminum sheet, one layer of polymer and the last layer of protective coating.

Physical Characteristic

| Item | Standard | Remarks |

|---|---|---|

| Panel Thickness | 4 mm | Available on request – 3mm, 5mm & 6 mm |

| Aluminium Cover Sheets thickness (Skin) | 0.5 mm | Available thickness 0.25mm to 0.55mm |

| Core | The thermoplastic core is LDPE | The thermoplastic core in Premium Bond panel is low density polyethylene (LDPE), belongs to carbon hydrogen plastic and it is non-toxic in nature. The final result after the burning of polyethylene is carbon, CO2, CO & H2O. |

| Panel Width | 1250 mm | ـــــــــ |

| Panel Length | 3200 mm | Can be adjusted as per requirement |

| Panel Weight | 5.5 kg /mm2 | ـــــــــ |

| Surface finish | Exterior face coil coated with PVDF (KYNAR -500, min 70%)Interior face coil coated with polyester | ـــــــــ |

Comment (1)

[…] Be sure to read: Advantages and technical specifications of premium bonded aluminum composite sheet […]