Important factors for implementation aluminum composite

factors for implementation aluminum composite

Qualitative and determining factors in the correct proper implementation of composite sheet are briefly explained:

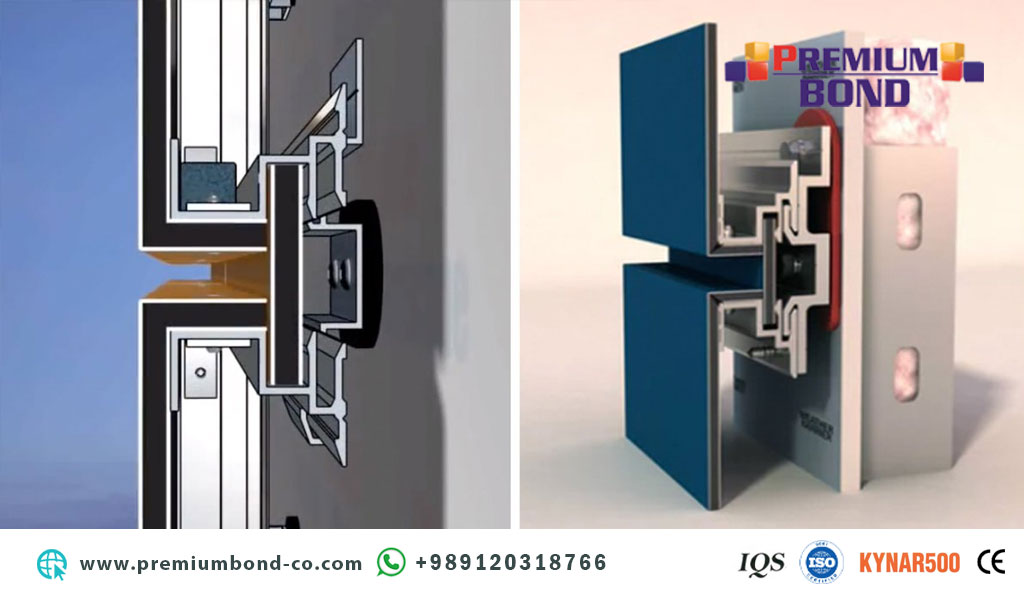

– Infrastructure should be done using suitable profiles (40 x 40 cans).

– Transverse and height gloves and profiles should be perfectly level and pliable.

– Cannabis exactly match the facade plan.

– Check all welded joints and have a suitable weld with a dimension of 5 mm.

– If the distance between the facade and the main wall of the building is large,

The length of the gloves has also been increased and the appropriate size gloves with the calculated connection should be used.

– Do not remove the protective label on the composite sheets until the end of the construction operation.

– After finishing the work, the composite sheets are bonded together

And if they are not stepped, the grooves should be in the same direction.

– Use composite sheets with a thickness of at least 4 mm (half a millimeter thick of each layer of aluminum and 3 mm thick core).

In designing the location of the seams is very important

Because it has a significant effect on the amount of waste, this should be calculated according to the dimensions of the composite sheet.

– Before buying composite sheets, consult with experts to buy the right composite sheets according to the conditions of the installation environment.

– Sealing of composite sheets after installation should be done completely using sealing rubber and silicone adhesive (in fixing method)

– To prevent corrosion between iron and aluminum, use dielectric rubber.

– Cutting in the corners of the parts (parts that are folded to form an upright angle) should be such that the seam does not fall in the corner because the parts do not weld after bending and this surviving seam, in addition to creating a rough appearance, absorbs water.

– The composite sheet produced in each factory has its own dimensions, care must be taken that the design is done according to the dimensions of the sheet.

Devices needed to run

Composite sheets are installed on the facade in the form of half-boxes. For the preparation of these sheets, cutting operations are performed from raw sheets, grooves, bending and assembly, which is done today using CNC machines.

Cutting and bending tools are also required.

Suitable weather conditions

Due to the fact that the facade is done outdoors, the only limitation is related to the time of precipitation or strong winds.

Storage conditions after implementation

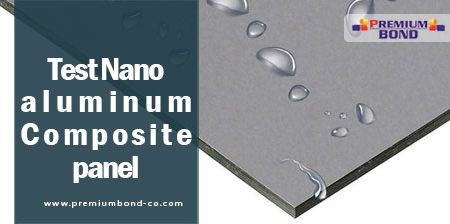

You should avoid hitting the facade with point objects. These facades are also washable and can be washed annually if they become dirty. In nano-composite sheets, rain washes the facade.

Comments (3)

[…] Learn more: Important factors for proper implementation […]

[…] Also read this article: Important factors for proper implementation […]

[…] Also read this article: Important factors for proper implementation […]