Composite and its application in panel making

COMPOSITES AND THEIR APPLICATIONS

Composite and its application in panel making

Today, advertising is the first word in identifying products or providing better services, and companies urgently need to use advertising techniques to grow their business and sell their products better than their competitors.

In addition to identifying the market and consumer needs, marketing and advertising require the use of advertising tools that are done in both traditional and modern ways.

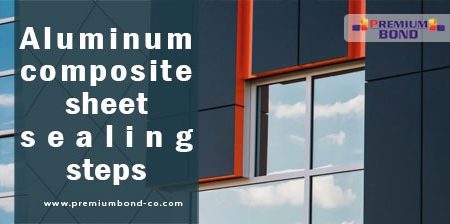

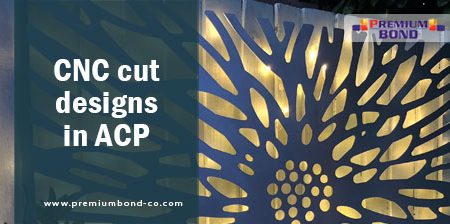

Modern advertising includes the Internet, social networks, animated banners on traditional sites and advertisements such as banner printing, tracts and billboards, which in various ways and branches, including Chelnium billboards, composites, billboards, flow signs, prominent billboards, steel billboards. , Shop signs and other items that can be implemented. In this article, we try to explain the composite and its application in panel making:

Composite sheet characteristics :

Resistant to weather conditions

Due to the presence of compressed polyethylene material, the best type of thermal insulation

Stainless

No color change

The beauty and radiance of the building’s facade

It has durability and long-term use

Quick and easy installation

Style

Automatic cleaning

Paintable

Fireproofing

Implementation in the desired colors of customers

A good platform to install all kinds of promotional letters

Also read this article: Need a shop sign

Composite sheet :

The composite sheet was first introduced by Premium bond in collaboration with BASF in 1969,

and today the composite panel uses composite panels in the facades of buildings.

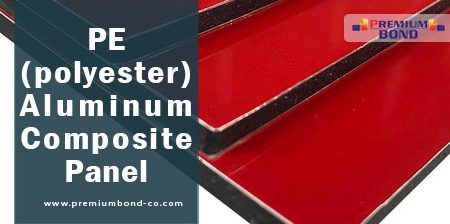

Composite panels are made of aluminum and polyethylene with a combination of three different technologies, which include extrusion, lamination with pre-made adhesive tapes, or a combination of extrusion and lamination, and is about 4 mm thick.

Composite sheets are used to cover the exterior and interior decoration of buildings, as well as partitions and false ceilings, because they consist of two layers of aluminum sheets in the outer shells and a layer of polyethylene or mineral refractories in the middle.

Due to their ingredients, these sheets have a high resistance to weather changes and sunlight and are considered as a kind of thermal insulation because having a smooth and shiny surface made of aluminum, the amount of light it receives from the sun is very small and this is why To prevent energy loss.

This sheet is obtained by combining aluminum and plastic and has a central layer that consists of polyethylene refractory as the central core of the panel, which includes two black and white colors, which in addition to the construction industry can be made of this material.

It has been used in various other industries such as petrochemicals and transportation. The most common use of these aluminum sheets is in renovating the facades of old buildings, decorating and interior facades of buildings, and partitions and visual facades.

Leave a Reply